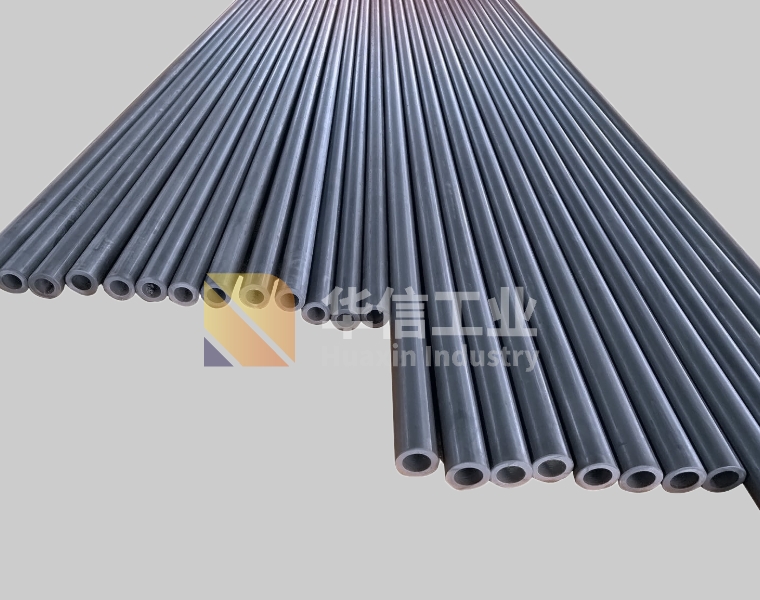

Silicon carbide ceramic cooling air pipes are advanced materials used in various industries for their excellent properties. These pipes are widely used in applications that require efficient heat dissipation and cooling, such as in power plants, chemical plants, and electronic devices.

The production process of silicon carbide ceramic cooling air pipes involves several steps. First, high-quality silicon carbide powder is mixed with a binder and formed into the desired shape. Then, the formed pipes are sintered at a high temperature to achieve a dense and strong ceramic structure. After sintering, the pipes are carefully inspected for quality and precision.

Silicon carbide ceramic cooling air pipes have several parameters that determine their performance. These parameters include the pipe diameter, length, wall thickness, and surface roughness. The diameter and length of the pipes can be customized to meet specific cooling requirements. The wall thickness is designed to ensure structural strength while allowing efficient heat transfer. The surface roughness is controlled to minimize air resistance and maximize cooling efficiency.

The usage scenarios of silicon carbide ceramic cooling air pipes are diverse. In power plants, these pipes are used to cool high-temperature gases and prevent equipment from overheating. In chemical plants, they are employed to cool corrosive gases and prevent damage to pipelines. In electronic devices, silicon carbide ceramic cooling air pipes are used to dissipate heat generated by components and ensure stable operation.

The advantages of using silicon carbide ceramic cooling air pipes are numerous. Firstly, their high thermal conductivity allows for efficient heat dissipation, ensuring optimal cooling performance. Secondly, their excellent corrosion resistance makes them suitable for use in harsh environments. Thirdly, their high mechanical strength and durability ensure a long service life. Lastly, their lightweight nature enables easy installation and maintenance.

In conclusion, silicon carbide ceramic cooling air pipes are essential components in various industries for their outstanding heat dissipation and cooling capabilities. The production process, parameters, and usage scenarios of these pipes have been discussed in this article. With their superior properties, these pipes play a crucial role in ensuring smooth and efficient operations in power plants, chemical plants, and electronic devices.