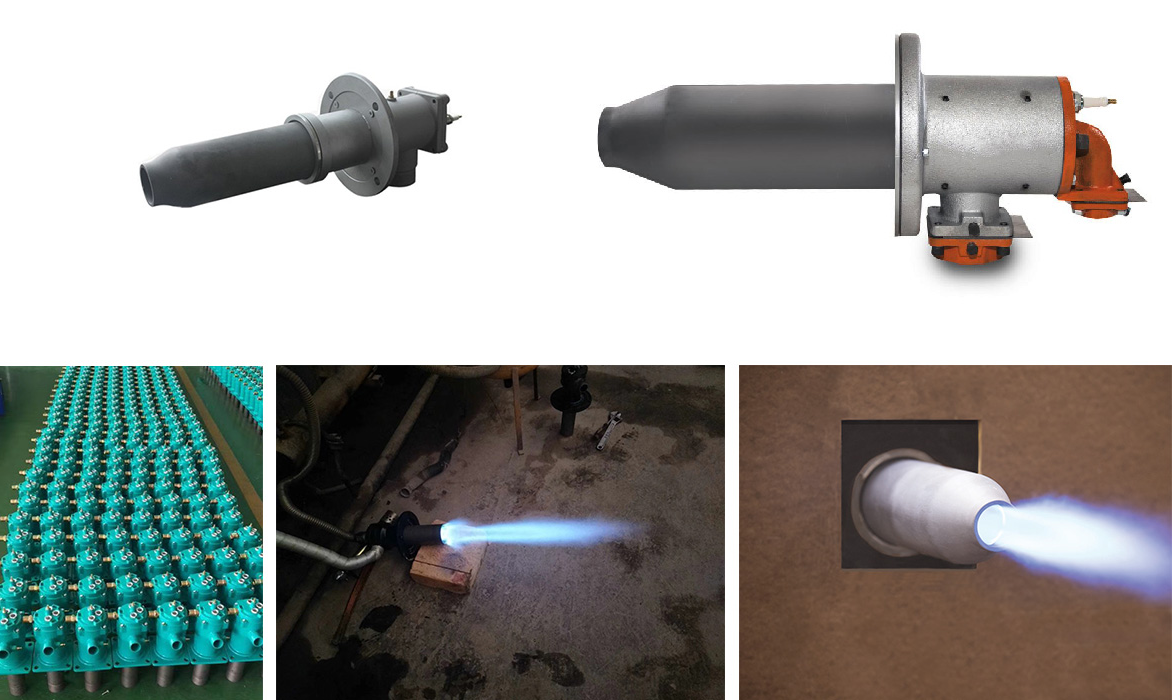

Silicon carbide burner nozzle is a high-performance wear-resistant and high-temperature flame-throwing device, which is widely used in sintering, sintering, smelting and other processes in industrial production. Silicon carbide flame nozzles have the advantages of high temperature resistance, corrosion resistance, wear resistance, etc., which can effectively improve production efficiency and product quality.

In industrial production, silicon carbide flame nozzles are mainly used in the following aspects:

1. Sintering: Silicon carbide flame nozzles can provide high temperature and high-speed airflow during the sintering process, helping raw materials to be rapidly sintered into shape, improving sintering efficiency and product quality.

2. Smelting: Silicon carbide flame nozzles can provide high-temperature and high-speed airflow during the smelting process, helping the smelting raw materials to melt quickly and improving smelting efficiency and product quality.

3. Reaction: Silicon carbide flame nozzles can provide high-temperature and high-speed airflow during chemical reactions, helping the reacting substances to react quickly and improving reaction efficiency and product purity.

4. Sintering sleeve: Silicon carbide flame nozzles can also be used as sintering sleeves, which can provide protection and stable atmosphere in high temperature environments to prevent oxidation of raw materials and degassing during the sintering process.

In general, silicon carbide flame nozzles have important application value in industrial production and can play an important role in various process links to improve production efficiency and product quality. The application range of silicon carbide flame nozzles is still expanding, and there will be broader development prospects in the future.